Drill charts are referred to when drilling holes in materials like wood, metal, concrete etc.

If you are a drilling expert, you probably already know the use and importance of drill charts in your work. But if you are just getting started in this field or pursuing it as a hobby, this guide will help you understand everything about drill charts.

Different materials have different surfaces, and therefore, they require different drilling speeds and techniques as well as bit sizes. A drill chart helps you with that.

Even if you have years of experience drilling in different materials, the drill chart can help you make your operations smoother.

Read the entire article to completely understand every aspect of drill charts, and by the time you complete reading this article, there will be no unanswered questions remain in your mind.

Best Charts, Graphs, and Diagram Tools

- 10 Best Online Chart Maker of 2023

- 10 Best Microsoft Visio Alternatives 2023

- 10 Best Org Chart Maker of 2023

- 10 Best UML Diagram Tools 2023

- 10 Best Entity Relationship Diagram (ERD) Tools 2023

What are drill charts?

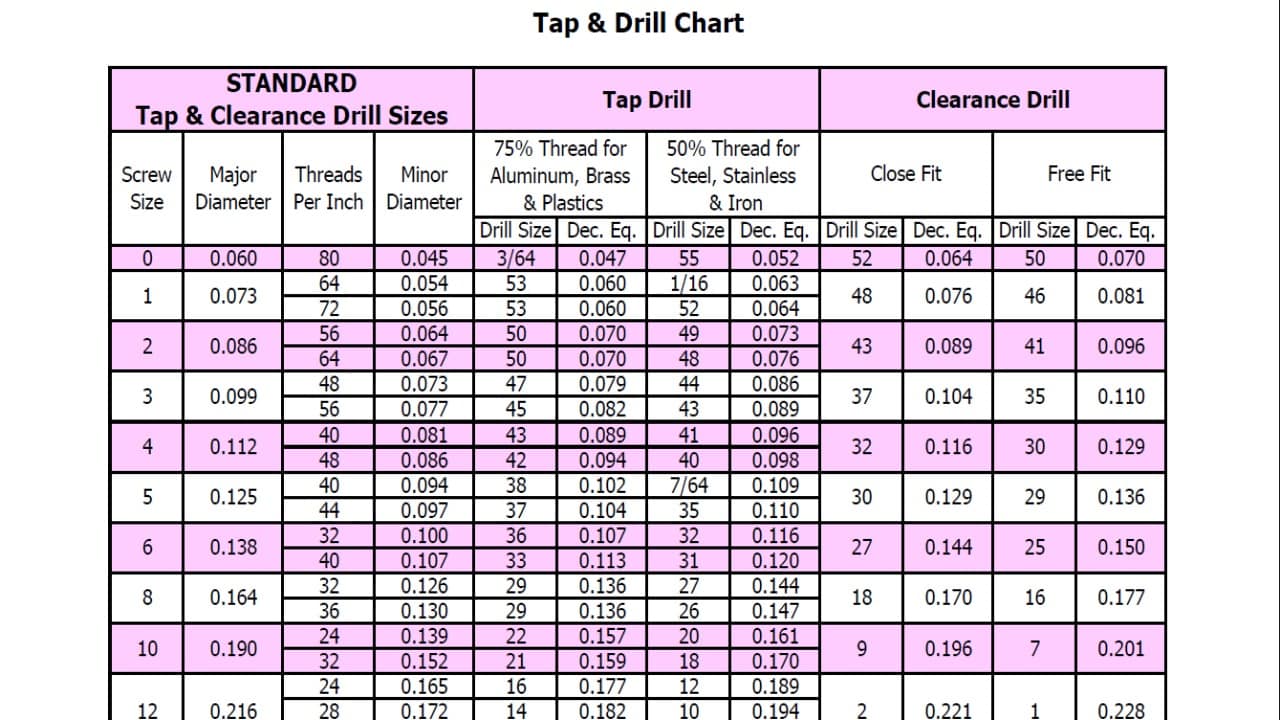

Drill charts (also known as drill tables) provide us useful information regarding drilling, such as bit size, tap size, thread depth, and more in a tabular form.

Drill Charts are specially useful for professionals like woodworkers, metal workers, plumbers, and such.

In a typical drill chart, there are rows and columns.

Each row represents an aspect or size, and the column represents information related to that aspect or size.

These charts are easily available on the internet, in reference books and in tools manuals.

Importance of drill charts

Below are some reasons to understand why drill charts are important to get the right drilling results.

Bit sizes

The drill chart contains information about the right drill bit size for many purposes. You need a drill with the correct diameter in order to make precise rules on the surface of the material. Mis-matching of these bits may result in loose connections or damaged material.

Compatibility of material

To make holes in different materials require different drilling speed and techniques. A drill chart helps you with that, too. Although general-purpose drill charts do not contain this information, you may find this information in the charts that are specifically designed for a particular material. Refer to those charts, as they will tell you what should be the right speed when drilling; it will save the drill bits from getting overheated or damaged.

Tap sizes

Drill charts are also useful when making thread depth for screw bolts. A chart tells you the tap sizes so that you get a secure and matching drill bit connection.

Thread depths

While making tap holes, it is also important that it gets enough depth. A drill chart helps you attain a strong and secure thread and also tells you how deep to drill for the thread.

Safety

The selection of wrong drill bits could result in accidents, damaged tools and workpiece damage. This happens if the work is done without prior research and planning. Having drill charts with you helps avoid this mishap while making operations run more efficiently and safely.

Understanding drill bit sizes

Drill charts provide an indispensable resource for understanding drill bit sizes. Measuring either inches or millimeters (or both), drill bit sizes represent the diameter of a drill bit along with details regarding its use and are listed alongside helpful information for its design and manufacturing process. Follow these steps to use drill bit sizes effectively:

Selecting material

To start off your drilling work efficiently, identify which material you will be drilling through; this could include wood, metal, plastic or concrete, among many others.

Select an appropriate bit

Select your drill bit according to its material and the size of the hole required, taking into consideration its impact on wear-resistant coatings to avoid excessive damage or wear and tear.

Set drill speeds

For each material and bit size listed on your chart, set your drill machine according to its recommended speed listed there.

Adopt an effective drilling technique

When drilling, adhere to best practices by maintaining steady pressure with even distribution, applying appropriate lubricant when necessary and wearing safety gear – paying particular attention to depth, angle and spacing during your drilling operations.

Effective use of drill charts

If you want to use the drill charts effectively, you need an organized approach. For the same, we have provided the steps below so that you can best take advantage of them.

Strategize your project

When starting any new project, the first and foremost thing is planning, which also includes drilling operations. To get the best out of any drilling operation, it is necessary that you have an accurate plan for it in advance, which also has details about materials, bit sizes, and depth requirements of holes that need to be created.

Once done planning, gather all the materials and tools required to start the work, such as drill bits, taps ( if applicable), safety gears, etc. Not to mention, always move ahead only after taking all the safety precautions.

Refer to a drill chart when planning your project

Drill charts are available in multiple formats. When making plans for your project, choose the one that best fits the materials being drilled as well as the drill bit size requirements for it.

Best Charts, Graphs, and Diagram Tools

- 10 Best Online Chart Maker of 2023

- 10 Best Microsoft Visio Alternatives 2023

- 10 Best Org Chart Maker of 2023

- 10 Best UML Diagram Tools 2023

- 10 Best Entity Relationship Diagram (ERD) Tools 2023

Configure your drill

Adjust the drill stroke settings as per the recommended RPM of the material and bit size. If necessary, create pilot holes before drilling larger holes – this will help guide and direct the drill bit while also preventing any possible mistakes.

Keep drilling under control

To get the maximum drilling performance, apply even and steady pressure throughout each drill stroke while moving at a controlled pace. If the bit becomes dull or hot while drilling, stop right away to cool. You can even replace it with a new one.

Tapping (if applicable)

Follow the instructions given in the drill chart when tapping holes. These instructions help you with thread size and depth. Also, the use of lubrication can make this process smoother.

Take safety precautions while working with power tools

Prioritize safety when handling powerful tools. Make sure to wear protective eyeglasses, hearing protection, and any other necessary. It will save you from accidents or injuries during any job you undertake.

Types of drill charts

As mentioned above, drill charts come in various shapes and forms to meet various industries or applications. Here are a few commonly used types that might come in handy in everyday life.

General-purpose drill charts

These charts provide basic information on drill bit sizes and speeds recommended for common materials like wood, metal and plastic – making them suitable for DIY as well as professional projects.

Metalworking drill charts

Metalworking drill charts provide guidance for drilling and tapping holes into metal materials. This may include guidance regarding high-speed steel (HSS) or carbide drill bits.

Woodworking drill charts

These Woodworking drill charts specialize in drilling through different types of wood, providing insights into ideal bit sizes and shapes for woodworking applications.

Concrete and masonry drill charts

These charts have been specifically created for workers working with concrete and masonry materials, providing guidance for using drill bits designed specifically for these applications while outlining general drilling techniques.

Pipe tap drill charts

Plumbers and others working with threaded pipes will find pipe tap drill charts essential, as they identify appropriate tap sizes and thread depths to threading pipes.

Fractional drill charts

Precision engineering and machining rely heavily on fractional, length and number drill charts as a means of selecting drill bits according to non-decimal systems of measurement.

Conclusion

Accuracy and precision are the most important factors when it comes to drilling. A drill chart can make your experience much smoother by saving you time, materials and frustration during this crucial journey.

Adherence to the recommendations found in a drill chart will allow for cleaner and more precise results, reduced accident risk and extended tool lifespan.

So the next time you pick up a drill, consult a drill chart as a source of guidance, and soon you will be enjoying successful drilling experiences.